| Introduction To Embroidery Monogramming | ||||||

Before we go deep into 3-rd party fonts, think it's important to describe the general situation in this entire subject of putting text and monograms on your projects. By saying "3-rd party embroidery alphabets", we relate to digitized fonts that are not built into your machine, or embroidery software. First - most embroidery machines include a few simple, most basic alphabets that you can easily use. Letters there are always re-scalable; you can adjust their size to fit your project. The same about embroidery programs that include limited number of pre-digitized fonts. The fonts there tend to be very simple, but still comfortable to use because you can type your desired "embroidery words" with keyboard, and adjust their size easily. So, why do we constantly search for other alphabets? Simple. Because the letters that can be found as "3-rd party fonts" tend to be a lot more beautiful than the "built-in" ones. There is a reason why "built-in" fonts can't be fancy. Because they must be re-sizable to more or less any size you wish, because they're built into your embroidery machine, and have to fit by size for everyone who owns this machine. The problem is that technically, you can digitize either something really nice but in limited number of sizes, or something really simple, but foolproof in terms of resizing. So, if your project asks for fancy letters - don't waste your time searching your embroidery machine or embroidery program. We carry a huge selection of fancy alphabets and monograms. So if you need some lovely monograms or just well digitized new alphabets - welcome to our little fonts heaven. All 3-rd party machine embroidery fonts work just like regular embroidery designs. At least we're not aware of other options. Each letter comes as separate file (design). And you can combine letters together to create your own text, or monograms. To join a few letters, you may use embroidery-editing software. For instance Embird, the software we so much in love with. Make sure that the letters combination you've made can fit into your hoop. With small letters it's rarely a problem unless you try to write A LOT OF TEXT at once. If you want to use large letters, and also create words with them, not only monograms - you'll need to embroider the letters one by one (or in small combination).

|

Saturday, April 10, 2010

How To Deal With Machine Embroidery Fonts

Tuesday, March 30, 2010

Dealing with Metallic Embroidery Thread

Dealing with Metallic Embroidery Thread!

Here are several tips for working with metallic thread. (These rules apply to any thread brand.) We hope that they help you to get the best out of your metallic thread, because they are definitely more challenging to handle than regular embroidery thread.

If you experience any trouble with metallic thread, please try the following steps, in this order:

1. Make sure you use a quality, new, SHARP "Metallic Needle." (Metallic needles have a larger eye, which allows metallic thread to run more smoothly. Often, this eye has Teflon coating, for even better effect.)

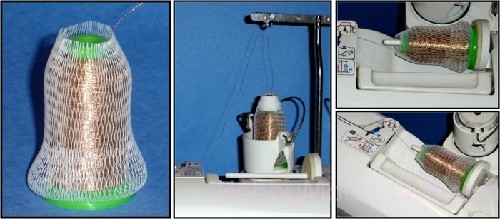

2. If you see that the thread is coming off the spool too easily and this is causing loops and knots at the very beginning, try using a thread net (spool net). These can really help with looping issues, and they cost only pennies. Below is shown what a thread net looks like (the first photo shows a closeup of thread net on metallic thread cone, the second is a photo on cone with net in vertical position, and the last two pictures - in horizontal cone position).

Find us on Ebay.

Here are several tips for working with metallic thread. (These rules apply to any thread brand.) We hope that they help you to get the best out of your metallic thread, because they are definitely more challenging to handle than regular embroidery thread.

If you experience any trouble with metallic thread, please try the following steps, in this order:

1. Make sure you use a quality, new, SHARP "Metallic Needle." (Metallic needles have a larger eye, which allows metallic thread to run more smoothly. Often, this eye has Teflon coating, for even better effect.)

2. If you see that the thread is coming off the spool too easily and this is causing loops and knots at the very beginning, try using a thread net (spool net). These can really help with looping issues, and they cost only pennies. Below is shown what a thread net looks like (the first photo shows a closeup of thread net on metallic thread cone, the second is a photo on cone with net in vertical position, and the last two pictures - in horizontal cone position).

| Most metallic thread, especially the brands that have a high sheen and really are "metallic," have looping problem. But it's an issue that is easy to solve, while the benefits of using shiny metallic thread are huge. | |

| |

| Another possible solution to "early looping" problems is to use a QUALITY vertical thread stand (thread feeder), as this issue is especially noticeable on machines that have horizontally positioned spool. If you have a good thread stand, it's worthwhile to try it. It is better to use thread stand staying separately from embroidery machine as far as possible to give time to metallic thread to relax. 3. Machine speed should be reduced. Try the lowest speed you can set on your machine, and observe the results. Move the speed up, little by little, until the point where it begins to cause thread breakage. Turn the speed down a bit down from there, to the best point of good performance. 4. Make sure the top thread tension is not too high for a metallic thread. Usually, metallic thread require a lower thread tension than regular embroidery thread. Lowering the tension can also help guard against shredding. 5. Make sure that your DESIGN is suitable for metallic. Many designs are digitized in such a way that they work badly with any metallic thread. When working with metallic thread, avoid the following designs: 5.1 Many overlapping objects that create 3 and more stitch layers 5.2 Designs with many small stitches 5.3 Designs with very dense areas 6. Make sure that you're using an appropriate backing. Metallic thread usually work MUCH better with backings that have a Viscose or Cotton component in them. 100% polyester backings are usually quite sturdy, and tend to create too much friction with needle and thread. This friction can cause unwanted thread breaks. Whenever you can, use a backing with a viscose or cotton component. Soft cutaway backings usually work best with metallic thread. 7. Make sure that you're using an appropriate fabric type. Fabric that is too thick or dense can cause unwanted friction, therefore causing metallic thread breakage. When working with metallic thread, always try to use soft materials and natural fibers. 8. Some metallic thread work better if they're cooled in a freezer for several minutes before embroidering. We hope these tips will help! If you have more suggestions or hints on how to use embroidery metallic thread we will be glad to hear them. | |

Sunday, March 28, 2010

7 Rules For Stabilizing - When, How, Why?

7 Rules For Stabilizing - When, How, Why?

We receive so many questions about embroidery stabilizers and see so many photos of projects ruined just because they haven't been stabilized properly. So we've decided to make a special page about stabilizing.

The rules of stabilizing are simple and logical. Once you understand what every type of stabilizer is supposed to do, its strong sides and its weak sides, you should be able to match an appropriate embroidery stabilizer for each project easily.

What Is An "Embroidery Stabilizer" and Why Should We Stabilize?

Embroidery stabilizers can be logically divided into two main types: "backings" and "toppings."

A "backing" is a piece of special material (usually non woven) that is placed UNDER the main fabric on which you intend to embroider, to make this fabric more stable.

Embroidery backings prevent fabric puckering, fabric stretching and deformation of embroideries after laundry.

"Topping", as you may already have guessed, is placed OVER the fabric on which you want to embroider.

Embroidery topping is a special material that is designed to stop embroidery stitches from "sinking" into stitches-absorbing types of fabric. For example - if you embroider on fleece, jersey, terry cloth, velvet, corduroy, artificial fur and so on - using embroidery topping is simply a must. If you neglect to do this, your precious project will be hopelessly ruined. A topping is also great to use if you want your design to "stand out" a little, even on regular fabric.

Embroidery toppings usually remind embroiderers of nylon film. But don't be fooled - they shouldn't be made out of nylon.

Most often, embroidery toppings are made out of gelatin-based water soluble substance, and easily get dissolved in warm water once your embroidery is finished. These water-soluble toppings are also called "wash-away", because they are easily washed away.

Another type of embroidery topping is heat-away, and they are removed with a hot iron. These ones are tricky. If you get a quality heat-away topping, it will be a blessing. A bad type, however, may leave you VERY angry and disappointed. Why? You'll discover below, once we explain when it's best to use each topping type.

Easy Rules for Stabilizing - When, How, and Why?

1. Stitches-absorbing fabric:

If you embroider on towels, velvet, fleece or other stitches-absorbing types of fabric, be sure to use topping film, to prevent stitches from sinking into the fabric. This is VERY important - without topping, such projects may be ruined.

There are two different types of embroidery toppings available - ones that are washed away with water, and ones that are removed with hot iron.

1.1 Heat-away topping:

The beauty of heat-away topping is that you remove it without wetting your project. Naturally, this is the only option when you're dealing with project that can't be washed. Using heat-away topping is convenient and fast, so you may want to use it whenever your fabric can stand a relatively hot iron. (Unless you just love to use wash-away anywhere you can).

The heat-away topping that we carry requires iron temperature of 260F (120C) (or higher). So, if your fabric can stand this temperature - you may use heat-away.

You hoop your fabric the regular way, place a piece of topping above the fabric, and embroider your design. Once the embroidery is finished, remove the hoop, cut away the large pieces of topping, put a piece of regular paper over the embroidery and iron it through that piece of paper.

The topping will remain on the paper; your embroidery will look great, smell great; and your iron will remain clean this way. You may shop for Heat-Away Topping here....

Heat-away topping tips:

1. If you're not sure whether your fabric supports 260F (120C) iron temperature - take a tiny test-piece of it, and try to iron, through a piece of paper. You'll know at once.

2. If a low quality heat-away backing is used, it may leave stains and unpleasant smell. So be careful to shop for good stuff.

3. NEVER use steam iron with heat-away topping.

1.2 Thin Wash-away topping:

Use thin wash-away topping every time that your fabric is not suitable for use with heat-away topping and wetting your project is not an issue. Visit this page to shop for thin Water-Soluble Topping.

1.3 Thick Wash-away topping:

Use thick wash-away topping with really high-pile fabrics, when you would normally use two layers of thin water-soluble film. Visit this page to get some thick Water-Soluble Topping. If your fabric can support either water soluble of heat away topping - use the type you like more. It may certainly be a matter of personal preference.

Here's a link to Water Soluble Topping film we use and highly recommend.

2. Heavier vs. Lighter fabric:

The heavier your fabric is, the heavier the weight of embroidery stabilizer that should be used; the lighter the fabric, the lighter machine embroidery stabilizer is recommended.

3. Denser vs. Transparent fabric:

The denser your embroidery design, the heavier the weight of stabilizer you should use; the less dense the design, the lighter backing is more recommended.

4. Using metallic thread:

If you're using metallic thread, avoid 100% polyester embroidery stabilizer. Try to use embroidery stabilizers with some natural component (cotton or poly-viscose). Natural machine embroidery stabilizers are usually softer, create less friction with embroidery needle and thread, and therefore you embroider with less thread breaks. This is correct for any thread, but is especially noticeable with metallics.

5. Cutaway Stabilizer:

Stretchy and unstable fabrics work best with cut-away stabilizers, because this type of backing can be removed by cutting it away without stretching the embroidered fabric in process. If you embroider on some kind of light cloth (like a T-shirt), be sure to use thin, translucent No-Show Mesh Cutaway Embroidery Stabilizer.

6. Tear-Away Stabilizer:

Stable woven fabrics usually work well with tear-away embroidery stabilizer because, when you tear away the excess stabilizer, the fabric that is stable won't stretch or become deformed. And it is a pleasure to use tear-away embroidery stabilizer when possible, because when it is removed, the back side of the embroidery looks better than after using cutaway (less backing edges can be seen).

Here are shortcuts to purchase two most popular types of tear away that we carry:

6.1 One is 100% Cotton Tear-Away Embroidery Stabilizer and can be ironed on to fabric - quilters just love it. It becomes VERY soft and pleasant after laundry.

6.2 The second one is more universal Poly-Viscose Tear-Away Embroidery Stabilizer, a little more stable than the above cotton embroidery stabilizer.

7. Water-Soluble Backing Stabilizer:

If, for some reason, you need the stabilizer to be removed completely (for example, if you embroider on organza, or create cut-work or stand-alone lace), use strong Water-Soluble Stabilizer as backing.

Usually we prefer to use fabric-type Water Soluble Stabilizer, because it practically doesn't stretch, "sits" great in hoop, and behaves like regular non woven fabric until you wash it away. Fabric type water-soluble stabilizer also doesn't stiffen at all and can be stored for many years without losing it's good qualities.

8. Heat-Away Backing:

If one of the following situations apply, use fusible (heat-away) backing that can be removed from the embroidered item by using a hot iron:

8.1 Your fabric and design need embroidery stabilizer to remain under the stitches, but you can't use tear-away or cut-away (the design and/or fabric may be too delicate for tear-away and/or too sheer for cut-away).

8.2 Your project is NOT WASHABLE, too delicate for tear-away and/or too sheer for cutaway.

8.3 You're working with some special technique, like making lace at an edge, and water soluble stabilizer isn't enough.

8.4 You want to create stand-alone embroidery from a design that was not digitized as stand-alone (you can just embroider on fusible embroidery stabilizer, cut the excess, then heat away the edges).

You may wonder why water-soluble embroidery stabilizer is more frequently used for correctly digitized lace designs. The reason is that it's much easier to remove water-soluble stabilizer.

CAUTION: NEVER, NEVER, NEVER use a STEAM iron with fusible stabilizer. The stabilizer will melt and ruin your fabric.

Here may be purchased Fusible Heat-Away Embroidery Stabilizer..

How To Store?

Many machine embroidery stabilizers look alike and are available in different weights, so it may be a good idea to keep them in the original packaging or in clearly marked bags. The identifying information you might need is the following:

1. Name and type of stabilizer

2. Weight of stabilizer

3. Its use

4. Brand ( to make sure you restock only the best ones )

We welcome everybody to share theirs knowledge, tips and tricks of stabilizing.

Find us on Ebay.

We receive so many questions about embroidery stabilizers and see so many photos of projects ruined just because they haven't been stabilized properly. So we've decided to make a special page about stabilizing.

The rules of stabilizing are simple and logical. Once you understand what every type of stabilizer is supposed to do, its strong sides and its weak sides, you should be able to match an appropriate embroidery stabilizer for each project easily.

What Is An "Embroidery Stabilizer" and Why Should We Stabilize?

Embroidery stabilizers can be logically divided into two main types: "backings" and "toppings."

A "backing" is a piece of special material (usually non woven) that is placed UNDER the main fabric on which you intend to embroider, to make this fabric more stable.

Embroidery backings prevent fabric puckering, fabric stretching and deformation of embroideries after laundry.

"Topping", as you may already have guessed, is placed OVER the fabric on which you want to embroider.

Embroidery topping is a special material that is designed to stop embroidery stitches from "sinking" into stitches-absorbing types of fabric. For example - if you embroider on fleece, jersey, terry cloth, velvet, corduroy, artificial fur and so on - using embroidery topping is simply a must. If you neglect to do this, your precious project will be hopelessly ruined. A topping is also great to use if you want your design to "stand out" a little, even on regular fabric.

Embroidery toppings usually remind embroiderers of nylon film. But don't be fooled - they shouldn't be made out of nylon.

Most often, embroidery toppings are made out of gelatin-based water soluble substance, and easily get dissolved in warm water once your embroidery is finished. These water-soluble toppings are also called "wash-away", because they are easily washed away.

Another type of embroidery topping is heat-away, and they are removed with a hot iron. These ones are tricky. If you get a quality heat-away topping, it will be a blessing. A bad type, however, may leave you VERY angry and disappointed. Why? You'll discover below, once we explain when it's best to use each topping type.

Easy Rules for Stabilizing - When, How, and Why?

1. Stitches-absorbing fabric:

If you embroider on towels, velvet, fleece or other stitches-absorbing types of fabric, be sure to use topping film, to prevent stitches from sinking into the fabric. This is VERY important - without topping, such projects may be ruined.

There are two different types of embroidery toppings available - ones that are washed away with water, and ones that are removed with hot iron.

1.1 Heat-away topping:

The beauty of heat-away topping is that you remove it without wetting your project. Naturally, this is the only option when you're dealing with project that can't be washed. Using heat-away topping is convenient and fast, so you may want to use it whenever your fabric can stand a relatively hot iron. (Unless you just love to use wash-away anywhere you can).

The heat-away topping that we carry requires iron temperature of 260F (120C) (or higher). So, if your fabric can stand this temperature - you may use heat-away.

You hoop your fabric the regular way, place a piece of topping above the fabric, and embroider your design. Once the embroidery is finished, remove the hoop, cut away the large pieces of topping, put a piece of regular paper over the embroidery and iron it through that piece of paper.

The topping will remain on the paper; your embroidery will look great, smell great; and your iron will remain clean this way. You may shop for Heat-Away Topping here....

Heat-away topping tips:

1. If you're not sure whether your fabric supports 260F (120C) iron temperature - take a tiny test-piece of it, and try to iron, through a piece of paper. You'll know at once.

2. If a low quality heat-away backing is used, it may leave stains and unpleasant smell. So be careful to shop for good stuff.

3. NEVER use steam iron with heat-away topping.

1.2 Thin Wash-away topping:

Use thin wash-away topping every time that your fabric is not suitable for use with heat-away topping and wetting your project is not an issue. Visit this page to shop for thin Water-Soluble Topping.

1.3 Thick Wash-away topping:

Use thick wash-away topping with really high-pile fabrics, when you would normally use two layers of thin water-soluble film. Visit this page to get some thick Water-Soluble Topping. If your fabric can support either water soluble of heat away topping - use the type you like more. It may certainly be a matter of personal preference.

Here's a link to Water Soluble Topping film we use and highly recommend.

2. Heavier vs. Lighter fabric:

The heavier your fabric is, the heavier the weight of embroidery stabilizer that should be used; the lighter the fabric, the lighter machine embroidery stabilizer is recommended.

3. Denser vs. Transparent fabric:

The denser your embroidery design, the heavier the weight of stabilizer you should use; the less dense the design, the lighter backing is more recommended.

4. Using metallic thread:

If you're using metallic thread, avoid 100% polyester embroidery stabilizer. Try to use embroidery stabilizers with some natural component (cotton or poly-viscose). Natural machine embroidery stabilizers are usually softer, create less friction with embroidery needle and thread, and therefore you embroider with less thread breaks. This is correct for any thread, but is especially noticeable with metallics.

5. Cutaway Stabilizer:

Stretchy and unstable fabrics work best with cut-away stabilizers, because this type of backing can be removed by cutting it away without stretching the embroidered fabric in process. If you embroider on some kind of light cloth (like a T-shirt), be sure to use thin, translucent No-Show Mesh Cutaway Embroidery Stabilizer.

6. Tear-Away Stabilizer:

Stable woven fabrics usually work well with tear-away embroidery stabilizer because, when you tear away the excess stabilizer, the fabric that is stable won't stretch or become deformed. And it is a pleasure to use tear-away embroidery stabilizer when possible, because when it is removed, the back side of the embroidery looks better than after using cutaway (less backing edges can be seen).

Here are shortcuts to purchase two most popular types of tear away that we carry:

6.1 One is 100% Cotton Tear-Away Embroidery Stabilizer and can be ironed on to fabric - quilters just love it. It becomes VERY soft and pleasant after laundry.

6.2 The second one is more universal Poly-Viscose Tear-Away Embroidery Stabilizer, a little more stable than the above cotton embroidery stabilizer.

7. Water-Soluble Backing Stabilizer:

If, for some reason, you need the stabilizer to be removed completely (for example, if you embroider on organza, or create cut-work or stand-alone lace), use strong Water-Soluble Stabilizer as backing.

Usually we prefer to use fabric-type Water Soluble Stabilizer, because it practically doesn't stretch, "sits" great in hoop, and behaves like regular non woven fabric until you wash it away. Fabric type water-soluble stabilizer also doesn't stiffen at all and can be stored for many years without losing it's good qualities.

8. Heat-Away Backing:

If one of the following situations apply, use fusible (heat-away) backing that can be removed from the embroidered item by using a hot iron:

8.1 Your fabric and design need embroidery stabilizer to remain under the stitches, but you can't use tear-away or cut-away (the design and/or fabric may be too delicate for tear-away and/or too sheer for cut-away).

8.2 Your project is NOT WASHABLE, too delicate for tear-away and/or too sheer for cutaway.

8.3 You're working with some special technique, like making lace at an edge, and water soluble stabilizer isn't enough.

8.4 You want to create stand-alone embroidery from a design that was not digitized as stand-alone (you can just embroider on fusible embroidery stabilizer, cut the excess, then heat away the edges).

You may wonder why water-soluble embroidery stabilizer is more frequently used for correctly digitized lace designs. The reason is that it's much easier to remove water-soluble stabilizer.

CAUTION: NEVER, NEVER, NEVER use a STEAM iron with fusible stabilizer. The stabilizer will melt and ruin your fabric.

Here may be purchased Fusible Heat-Away Embroidery Stabilizer..

How To Store?

Many machine embroidery stabilizers look alike and are available in different weights, so it may be a good idea to keep them in the original packaging or in clearly marked bags. The identifying information you might need is the following:

1. Name and type of stabilizer

2. Weight of stabilizer

3. Its use

4. Brand ( to make sure you restock only the best ones )

We welcome everybody to share theirs knowledge, tips and tricks of stabilizing.

Find us on Ebay.

Subscribe to:

Posts (Atom)